[kc_row _id=”359878″ _collapse=”1″ disabled=”on”][kc_column width=”12/12″ video_mute=”no” _id=”397830″][kc_row_inner column_align=”middle” video_mute=”no” _id=”873140″][kc_column_inner width=”64.63%” _id=”802097″][kc_single_image image_size=”full” _id=”994278″ image_source=”media_library” image=”2514″ css_custom=”{`kc-css`:{`any`:{`image-style`:{`width|img`:`750px`,`max-width|img`:`2000px`,`margin|`:`inherit inherit 2px inherit`}}}}”][/kc_column_inner][kc_column_inner width=”35.34%” _id=”397856″][kc_title text=”UFJPRFVDVA==” _id=”538463″ type=”h1″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`,`text-transform|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`uppercase`,`text-align|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`left`}}}}”][kc_title text=”RXh0cnVzaW9uIExhbWluYXRpbmcgTWFjaGluZQ==” _id=”977421″ type=”h2″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-size|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`33px`,`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`}}}}”][kc_title text=”Rm9yIEZsZXhpYmxlIFBhY2thZ2luZyA=” _id=”947049″ type=”h4″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`400`,`text-align|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`left`,`margin|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`8px inherit 10px inherit`}}}}”][kc_column_text _id=”39471″ css_custom=”{`kc-css`:{`any`:{`typography`:{`text-align|,p`:`left`}}}}”]

Converters who want to enhance and upscale lamination quality and increase productivity at low conversion cost.

A step towards producing more sustainable plastic products and not only lighten the environmental footprint but also by producing recyclable and upcycle goods reduces the load on the waste management.

[/kc_column_text][kc_button text_title=”View More” _id=”832777″ custom_css=”{`kc-css`:{`any`:{`button-style`:{`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`12px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}” show_icon=”yes” icon=”flaticon-arrows” icon_position=”left”][kc_button text_title=”Brochure” icon=”flaticon-download” icon_position=”left” _id=”740002″ show_icon=”yes” custom_css=”{`kc-css`:{`any`:{`button-style`:{`color|.kc_button`:`#ffffff`,`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`10px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}”][/kc_column_inner][/kc_row_inner][kc_row_inner column_align=”middle” video_mute=”no” _id=”137134″][kc_column_inner width=”35.25%” _id=”80406″][kc_title text=”UFJPRFVDVA==” _id=”282362″ type=”h1″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`,`text-transform|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`uppercase`,`text-align|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`left`}}}}”][kc_title text=”Um90b2dyYXZ1cmUgUHJpbnRpbmcgUHJlc3M=” _id=”373462″ type=”h2″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-size|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`33px`,`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`}}}}”][kc_column_text _id=”506361″ css_custom=”{`kc-css`:{`any`:{`typography`:{`text-align|,p`:`left`}}}}”]

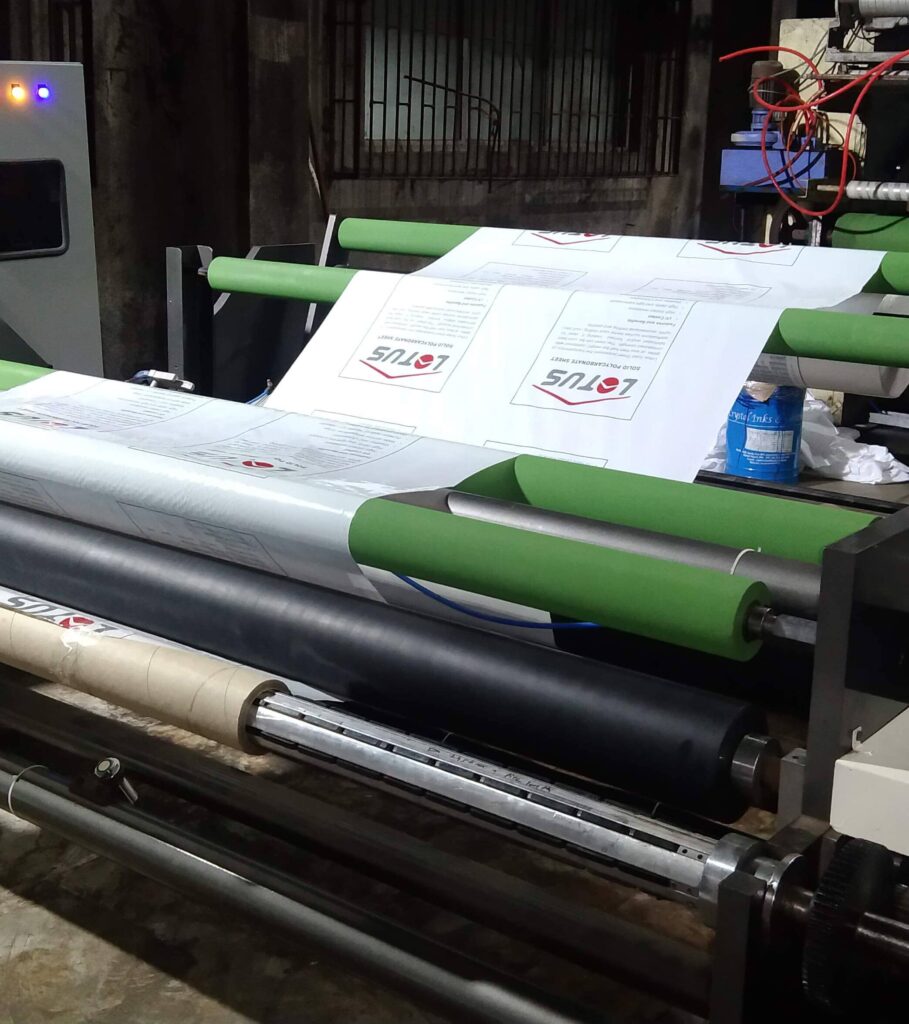

The new generation of Rotogravure Press is led by Electronic Line Shaft Technology (ELS). Some advantages compared to conventional mechanical transmissions are : better operator access around the press, reduction in noise level.

By perfectly integrating new generation of electronics and ergonomically designed mechanical components, the press is made to deliver optimum performance and productivity.

[/kc_column_text][kc_button text_title=”View More” _id=”953772″ custom_css=”{`kc-css`:{`any`:{`button-style`:{`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`12px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}” show_icon=”yes” icon=”flaticon-arrows” icon_position=”left”][kc_button text_title=”Brochure” icon=”flaticon-download” icon_position=”left” _id=”332502″ show_icon=”yes” custom_css=”{`kc-css`:{`any`:{`button-style`:{`color|.kc_button`:`#ffffff`,`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`10px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}”][/kc_column_inner][kc_column_inner width=”64.71%” _id=”299733″][kc_single_image image_size=”full” _id=”377045″ image_source=”media_library” image=”2515″ css_custom=”{`kc-css`:{`any`:{`image-style`:{`text-align|`:`right`,`width|img`:`750px`,`max-width|img`:`2000px`,`margin|`:`inherit inherit 5px inherit`}}}}”][/kc_column_inner][/kc_row_inner][kc_row_inner column_align=”middle” video_mute=”no” _id=”237766″][kc_column_inner width=”64.63%” _id=”362431″][kc_single_image image_size=”full” _id=”4756″ image_source=”media_library” image=”2514″ css_custom=”{`kc-css`:{`any`:{`image-style`:{`width|img`:`750px`,`max-width|img`:`2000px`,`margin|`:`inherit inherit 2px inherit`}}}}”][/kc_column_inner][kc_column_inner width=”35.34%” _id=”275672″][kc_title text=”UFJPRFVDVA==” _id=”507171″ type=”h1″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`,`text-transform|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`uppercase`,`text-align|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`left`}}}}”][kc_title text=”TGFtaW5hdGluZyBNYWNoaW5l” _id=”54577″ type=”h2″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-size|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`33px`,`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`}}}}”][kc_title text=”Um90b2dyYXZ1cmUgUHJpbnRpbmcgUHJlc3Mg” _id=”326779″ type=”h4″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`400`,`text-align|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`left`,`margin|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`8px inherit 10px inherit`}}}}”][kc_column_text _id=”162721″ css_custom=”{`kc-css`:{`any`:{`typography`:{`text-align|,p`:`left`}}}}”]

This modern new generation press is built to cater demands of the continuously evolving flexible packaging industries.

Machine is designed ergonomically to cater medium and long run length job.

High productivity, low conversion cost, high quality printing, fast job change-over are the key features.

[/kc_column_text][kc_button text_title=”View More” _id=”962650″ custom_css=”{`kc-css`:{`any`:{`button-style`:{`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`12px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}” show_icon=”yes” icon=”flaticon-arrows” icon_position=”left”][kc_button text_title=”Brochure” icon=”flaticon-download” icon_position=”left” _id=”735825″ show_icon=”yes” custom_css=”{`kc-css`:{`any`:{`button-style`:{`color|.kc_button`:`#ffffff`,`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`10px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}”][/kc_column_inner][/kc_row_inner][kc_row_inner column_align=”middle” video_mute=”no” _id=”797957″][kc_column_inner width=”35.25%” _id=”383964″][kc_title text=”UFJPRFVDVA==” _id=”916721″ type=”h1″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`,`text-transform|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`uppercase`,`text-align|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`left`}}}}”][kc_title text=”U2xpdHRlcg==” _id=”612630″ type=”h2″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-size|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`33px`,`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`}}}}”][kc_title text=”V2l0aCB0aGUgY29tYmluYXRpb24gb2YgcHJvdmVuIEFheWFyIGFuZCB3aXRoIHRoZSBhZHZhbnRhZ2VzIG9mIG91ciBtb2Rlcm4gdGVjaG5vbG9neS4=” _id=”418494″ type=”h4″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`400`,`text-align|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`left`,`margin|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`8px inherit 10px inherit`}}}}”][kc_column_text _id=”226262″ css_custom=”{`kc-css`:{`any`:{`typography`:{`text-align|,p`:`left`}}}}”]

Slitter is the ideal solution for the modern converter that demands to produce excellent quality rolls, by increasing the productivity, especially on the down-time between working cycles, while minimise the traditional bottlenecks in the slitting area.

[/kc_column_text][kc_button text_title=”View More” _id=”162540″ custom_css=”{`kc-css`:{`any`:{`button-style`:{`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`12px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}” show_icon=”yes” icon=”flaticon-arrows” icon_position=”left”][kc_button text_title=”Brochure” icon=”flaticon-download” icon_position=”left” _id=”348282″ show_icon=”yes” custom_css=”{`kc-css`:{`any`:{`button-style`:{`color|.kc_button`:`#ffffff`,`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`10px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}”][/kc_column_inner][kc_column_inner width=”64.71%” _id=”543751″][kc_single_image image_size=”full” _id=”166710″ image_source=”media_library” image=”2515″ css_custom=”{`kc-css`:{`any`:{`image-style`:{`text-align|`:`right`,`width|img`:`750px`,`max-width|img`:`2000px`,`margin|`:`inherit inherit 5px inherit`}}}}”][/kc_column_inner][/kc_row_inner][kc_row_inner column_align=”middle” video_mute=”no” _id=”459706″][kc_column_inner width=”64.63%” _id=”170928″][kc_single_image image_size=”full” _id=”809425″ image_source=”media_library” image=”2514″ css_custom=”{`kc-css`:{`any`:{`image-style`:{`width|img`:`750px`,`max-width|img`:`2000px`,`margin|`:`inherit inherit 2px inherit`}}}}”][/kc_column_inner][kc_column_inner width=”35.34%” _id=”307903″][kc_title text=”UFJPRFVDVA==” _id=”594858″ type=”h1″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`,`text-transform|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`uppercase`,`text-align|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`left`}}}}”][kc_title text=”Um90b2dyYXZ1cmUgUHJpbnRpbmcgUHJlc3MgTWVjaGFuaWNhbCBsaW5l” _id=”424435″ type=”h2″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-size|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`33px`,`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`}}}}”][kc_title text=”Um90b2dyYXZ1cmUgUHJpbnRpbmcgUHJlc3Mg” _id=”910405″ type=”h4″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`400`,`text-align|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`left`,`margin|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`8px inherit 10px inherit`}}}}”][kc_column_text _id=”267056″ css_custom=”{`kc-css`:{`any`:{`typography`:{`text-align|,p`:`left`}}}}”]

The Press is built with Mechanical line shaft with servo technology.

By perfectly integrating the new generation of electronics and ergonomically designed mechanical components, the machine is made to deliver optimum performance and productivity.

[/kc_column_text][kc_button text_title=”View More” _id=”993980″ custom_css=”{`kc-css`:{`any`:{`button-style`:{`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`12px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}” show_icon=”yes” icon=”flaticon-arrows” icon_position=”left”][kc_button text_title=”Brochure” icon=”flaticon-download” icon_position=”left” _id=”8777″ show_icon=”yes” custom_css=”{`kc-css`:{`any`:{`button-style`:{`color|.kc_button`:`#ffffff`,`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`10px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}”][/kc_column_inner][/kc_row_inner][kc_row_inner column_align=”middle” video_mute=”no” _id=”670281″][kc_column_inner width=”35.25%” _id=”539188″][kc_title text=”UFJPRFVDVA==” _id=”635738″ type=”h1″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`,`text-transform|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`uppercase`,`text-align|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`left`}}}}”][kc_title text=”U29sdmVudCAtIExlc3MgTGFtaW5hdG9y” _id=”15676″ type=”h2″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-size|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`33px`,`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`500`}}}}”][kc_column_text _id=”376265″ css_custom=”{`kc-css`:{`any`:{`typography`:{`text-align|,p`:`left`}}}}”]

The machine is designed to handle a wide range of laminating jobs and to cater growing needs of solvent-less lamination on flexible packaging market.

High productivity, easy operating, optimum energy consumption and ability to handle wide range of laminating jobs are the key features.

By perfectly integration of the new generation of electronics and ergonomically designed mechanical components, the machine is made to deliver optimum performance and productivity.

[/kc_column_text][kc_button text_title=”View More” _id=”265961″ custom_css=”{`kc-css`:{`any`:{`button-style`:{`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`12px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}” show_icon=”yes” icon=”flaticon-arrows” icon_position=”left”][kc_button text_title=”Brochure” icon=”flaticon-download” icon_position=”left” _id=”952355″ show_icon=”yes” custom_css=”{`kc-css`:{`any`:{`button-style`:{`color|.kc_button`:`#ffffff`,`background-color|.kc_button`:`#1e73be`,`text-align|`:`left`,`margin|.kc_button`:`10px inherit inherit inherit`},`mouse-hover`:{`color|.kc_button:hover`:`#ffffff`,`background-color|.kc_button:hover`:`#000000`}}}}”][/kc_column_inner][kc_column_inner width=”64.71%” _id=”419208″][kc_single_image image_size=”full” _id=”605504″ image_source=”media_library” image=”2515″ css_custom=”{`kc-css`:{`any`:{`image-style`:{`text-align|`:`right`,`width|img`:`750px`,`max-width|img`:`2000px`,`margin|`:`inherit inherit 5px inherit`}}}}”][/kc_column_inner][/kc_row_inner][/kc_column][/kc_row][kc_row _id=”168165″ _collapse=”1″ disabled=”on”][kc_column width=”12/12″ video_mute=”no” _id=”597177″][kc_single_image image_size=”full” custom_link=”#” icon=”fa-plus” _id=”719314″ image=”3462″ image_source=”media_library”][kc_row_inner column_align=”middle” video_mute=”no” _id=”523980″][kc_column_inner width=”64.63%” _id=”121261″][kc_spacing height=”25px” _id=”510579″][kc_title text=”U3VyZmFjZSBQcm90ZWN0aXZlIEZpbG0gQ29hdGluZw==” _id=”532719″ type=”h2″][kc_spacing height=”20″ _id=”258999″][kc_column_text _id=”929889″ css_custom=”{`kc-css`:{`any`:{`typography`:{`font-size|,p`:`16px`}}}}”]

This modern new generation press is built to cater demands of the continuously evolving flexible packaging industries. Machine is designed ergonomically to cater medium and long run length job.

High productivity, low conversion cost, high quality printing, fast job change-over are the key features.

[/kc_column_text][kc_spacing height=”20″ _id=”134463″][kc_button text_title=”Brochure” _id=”661525″ link=”#||” show_icon=”yes” icon=”flaticon-download” icon_position=”left” custom_css=”{`kc-css`:{}}”][/kc_column_inner][kc_column_inner width=”35.34%” _id=”744630″][kc_spacing height=”40px” _id=”578723″][kc_raw_code code=”PHN0eWxlPg0KdGFibGUuYmx1ZVRhYmxlIHsNCiAgYm9yZGVyOiAxcHggc29saWQgIzFDNkVBNDsNCiAgYmFja2dyb3VuZC1jb2xvcjogI2Y1ZjVmNTsNCiAgd2lkdGg6IDEwMCU7DQogIHRleHQtYWxpZ246IGxlZnQ7DQogIGJvcmRlci1jb2xsYXBzZTogY29sbGFwc2U7DQp9DQp0YWJsZS5ibHVlVGFibGUgdGQsIHRhYmxlLmJsdWVUYWJsZSB0aCB7DQogIGJvcmRlcjogMXB4IHNvbGlkICMwMDAwMDA7DQogIHBhZGRpbmc6IDNweCA0cHg7DQp9DQp0YWJsZS5ibHVlVGFibGUgdGJvZHkgdGQgew0KICBmb250LXNpemU6IDEzcHg7DQogIGNvbG9yOiAjMDAwMDAwOw0KfQ0KdGFibGUuYmx1ZVRhYmxlIHRoZWFkIHsNCiBiYWNrZ3JvdW5kOiAjMGI1NDZiOw0KIGJhY2tncm91bmQ6IC1tb3otbGluZWFyLWdyYWRpZW50KHRvcCwgIzEyNmI4NyAwJSwgIzBiNTQ2YiA2NiUsICMwNjQ1NTkgMTAwJSk7DQogYmFja2dyb3VuZDogLXdlYmtpdC1saW5lYXItZ3JhZGllbnQodG9wLCAjMTI2Yjg3IDAlLCAjMGI1NDZiIDY2JSwgIzA2NDU1OSAxMDAlKTsNCiBiYWNrZ3JvdW5kOiBsaW5lYXItZ3JhZGllbnQodG8gYm90dG9tLCAjMTI2Yjg3IDAlLCAjMGI1NDZiIDY2JSwgIzA2NDU1OSAxMDAlKTsNCiAgYm9yZGVyLWJvdHRvbTogMnB4IHNvbGlkICM0NDQ0NDQ7DQp9DQp0YWJsZS5ibHVlVGFibGUgdGhlYWQgdGggew0KICBmb250LXNpemU6IDE1cHg7DQogIC8qIGZvbnQtd2VpZ2h0OiBib2xkOyAqLw0KICBjb2xvcjogI0ZGRkZGRjsNCiAgdGV4dC1hbGlnbjogY2VudGVyOw0KICBib3JkZXItbGVmdDogMnB4IHNvbGlkICMwMDMxNDA7DQp9DQp0YWJsZS5ibHVlVGFibGUgdGhlYWQgdGg6Zmlyc3QtY2hpbGQgew0KICBib3JkZXItbGVmdDogbm9uZTsNCn0NCg0KdGFibGUuYmx1ZVRhYmxlIHRmb290IHRkIHsNCiAgZm9udC1zaXplOiAxNHB4Ow0KfQ0KdGFibGUuYmx1ZVRhYmxlIHRmb290IC5saW5rcyB7DQogIHRleHQtYWxpZ246IHJpZ2h0Ow0KfQ0KdGFibGUuYmx1ZVRhYmxlIHRmb290IC5saW5rcyBhew0KICBkaXNwbGF5OiBpbmxpbmUtYmxvY2s7DQogIGJhY2tncm91bmQ6ICMxQzZFQTQ7DQogIGNvbG9yOiAjRkZGRkZGOw0KICBwYWRkaW5nOiAycHggOHB4Ow0KICBib3JkZXItcmFkaXVzOiA1cHg7DQp9DQo8L3N0eWxlPg0KDQo8c3R5bGUgdHlwZT0idGV4dC9jc3MiPg0KLnRnICB7Ym9yZGVyLWNvbGxhcHNlOmNvbGxhcHNlO2JvcmRlci1zcGFjaW5nOjA7fQ0KLnRnIHRke2JvcmRlci1jb2xvcjpibGFjaztib3JkZXItc3R5bGU6c29saWQ7Ym9yZGVyLXdpZHRoOjFweDtmb250LWZhbWlseTpBcmlhbCwgc2Fucy1zZXJpZjtmb250LXNpemU6MTRweDsNCiAgb3ZlcmZsb3c6aGlkZGVuO3BhZGRpbmc6MTBweCA1cHg7d29yZC1icmVhazpub3JtYWw7fQ0KLnRnIHRoe2JvcmRlci1jb2xvcjpibGFjaztib3JkZXItc3R5bGU6c29saWQ7Ym9yZGVyLXdpZHRoOjFweDtmb250LWZhbWlseTpBcmlhbCwgc2Fucy1zZXJpZjtmb250LXNpemU6MTRweDsNCiAgZm9udC13ZWlnaHQ6bm9ybWFsO292ZXJmbG93OmhpZGRlbjtwYWRkaW5nOjEwcHggNXB4O3dvcmQtYnJlYWs6bm9ybWFsO30NCi50ZyAudGctZGNkY3tmb250LXNpemU6MThweDsgYmFja2dyb3VuZC1jb2xvcjojMUU3M0JFO2NvbG9yOiNmZmZmZmY7IHRleHQtYWxpZ246Y2VudGVyO3ZlcnRpY2FsLWFsaWduOnRvcH0NCi50ZyAudGctMGxheHt0ZXh0LWFsaWduOmNlbnRlcjt2ZXJ0aWNhbC1hbGlnbjp0b3B9DQo8L3N0eWxlPg0KDQo8dGFibGUgY2xhc3M9InRnIj4NCjxjb2xncm91cCA+DQoJPGNvbCBzdHlsZT0id2lkdGg6NjAlOyI+DQoJPGNvbCBzdHlsZT0id2lkdGg6NDAlOyI+DQo8L2NvbGdyb3VwPg0KPHRib2R5Pg0KICA8dHI+DQogICAgPHRoIGNsYXNzPSJ0Zy1kY2RjIiBjb2xzcGFuPSIyIj5TdGFuZGFyZCBUZWNobmljYWwgU3BlY2lmaWNhdGlvbjwvdGg+DQogIDwvdHI+DQoNCiAgPHRyPg0KICAgIDx0ZD5NYXhpbXVtIHdlYiB3aWR0aDwvdGQ+DQogICAgPHRkPjEzMDAgbW08L3RkPg0KICA8L3RyPg0KICA8dHI+DQogICAgPHRkPlByaW50aW5nIGN5bGluZGVyIHJlcGVhdCByYW5nZTwvdGQ+DQogICAgPHRkPjQ1MCB0byA5MjAgbW08L3RkPg0KICA8L3RyPg0KICA8dHI+DQogICAgPHRkPk1heGltdW0gbWVjaGFuaWNhbCBzcGVlZDwvdGQ+DQogICAgPHRkPjQ1MCBtL21pbjwvdGQ+DQogIDwvdHI+DQogIDx0cj4NCiAgICA8dGQ+V2ViIHRlbnNpb24gcmFuZ2U8L3RkPg0KICAgIDx0ZD42MCB0byA0MDAgTjwvdGQ+DQogIDwvdHI+DQogIDx0cj4NCiAgICA8dGQ+U3RhbmRhcmQgZHJ5aW5nIGhvb2QgbGVuZ3RoPC90ZD4NCiAgICA8dGQ+Mi4wIG10cjwvdGQ+DQogIDwvdHI+DQogIDx0cj4NCiAgICA8dGQ+UmVlbCBkaWFtZXRlcjwvdGQ+DQogICAgPHRkPjEwMDAgbW08L3RkPg0KICA8L3RyPg0KPC90Ym9keT4NCjwvdGFibGU+” _id=”253618″][/kc_column_inner][/kc_row_inner][kc_row_inner column_align=”middle” video_mute=”no” _id=”195194″][kc_column_inner width=”33.33%” _id=”386751″][kc_spacing height=”50px” _id=”245616″][kc_single_image image_size=”full” _id=”833064″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”33.33%” _id=”220984″][kc_spacing height=”50px” _id=”405241″][kc_single_image image_size=”full” _id=”946580″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”33.33%” _id=”842046″][kc_spacing height=”50px” _id=”764931″][kc_single_image image_size=”full” _id=”229049″ image_source=”media_library” image=”3462″][/kc_column_inner][/kc_row_inner][kc_row_inner column_align=”middle” video_mute=”no” _id=”495074″][kc_column_inner width=”64.63%” _id=”418195″][kc_spacing height=”60px” _id=”714354″][kc_title text=”U3VyZmFjZSBQcm90ZWN0aXZlIEZpbG0gQ29hdGluZyBNYW51ZmFjdHVyZSBieTxicj4NCkFBWUFSIElOVEVSTkFUSU9OQUw=” _id=”592161″ type=”h4″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-size|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`30px`,`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`300`}}}}”][/kc_column_inner][kc_column_inner width=”35.34%” _id=”661743″][kc_spacing height=”60px” _id=”616438″][kc_title text=”VGhlIE1hY2hpbmU=” _id=”992528″ type=”h4″ css_custom=”{`kc-css`:{`any`:{`title-style`:{`font-size|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`30px`,`font-weight|+.kc_title,.kc_title,.kc_title a.kc_title_link`:`300`}}}}”][kc_spacing height=”20″ _id=”107104″][kc_column_text _id=”351768″ css_custom=”{`kc-css`:{`any`:{`typography`:{`font-size|,p`:`16px`}}}}”]

The new generation Rotogravure Press is led by ELS technology. By perfectly integration of advanced electronics and ergonomically designed mechanical components to deliver optimum performance, Better operational ease, faster print register response, higher productivity, better print quality, less waste, optimizing ink solvent and energy consumption, faster job changeover etc.

[/kc_column_text][/kc_column_inner][/kc_row_inner][kc_row_inner column_align=”middle” video_mute=”no” _id=”247337″][kc_column_inner width=”100%” _id=”555855″][kc_spacing height=”60px” _id=”742225″][kc_single_image image_size=”full” _id=”111879″ image_source=”media_library” image=”3462″][kc_spacing height=”60px” _id=”428118″][/kc_column_inner][/kc_row_inner][kc_accordion _id=”69759″][kc_accordion_tab title=”Service Cart (Trolley System)” _id=”385502″][kc_row_inner column_align=”middle” video_mute=”no” _id=”200202″][kc_column_inner width=”50%” _id=”51033″][kc_single_image image_size=”full” _id=”878522″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”784031″][kc_column_text _id=”483752″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”567099″][kc_column_text _id=”71727″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Print Station Controls” _id=”538010″][kc_row_inner column_align=”middle” video_mute=”no” _id=”717947″][kc_column_inner width=”50%” _id=”983542″][kc_single_image image_size=”full” _id=”690903″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”390707″][kc_column_text _id=”563562″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”55412″][kc_column_text _id=”729782″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”High Efficient Ventilation Module” _id=”373127″][kc_row_inner column_align=”middle” video_mute=”no” _id=”954899″][kc_column_inner width=”50%” _id=”538024″][kc_single_image image_size=”full” _id=”780143″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”617905″][kc_column_text _id=”179975″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”765010″][kc_column_text _id=”752202″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Unique Designed Doctor Blade Group” _id=”518755″][kc_row_inner column_align=”middle” video_mute=”no” _id=”909864″][kc_column_inner width=”50%” _id=”416896″][kc_single_image image_size=”full” _id=”480845″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”143475″][kc_column_text _id=”474751″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”323433″][kc_column_text _id=”190817″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Unwind Group” _id=”299567″][kc_row_inner column_align=”middle” video_mute=”no” _id=”696″][kc_column_inner width=”50%” _id=”7867″][kc_single_image image_size=”full” _id=”721954″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”959822″][kc_column_text _id=”155050″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”876472″][kc_column_text _id=”692475″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”In-Feed Web Handling Control” _id=”957979″][kc_row_inner column_align=”middle” video_mute=”no” _id=”2202″][kc_column_inner width=”50%” _id=”695133″][kc_single_image image_size=”full” _id=”626383″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”218797″][kc_column_text _id=”407664″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”61831″][kc_column_text _id=”818816″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Control System” _id=”827716″][kc_row_inner column_align=”middle” video_mute=”no” _id=”590845″][kc_column_inner width=”50%” _id=”543199″][kc_single_image image_size=”full” _id=”802762″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”311910″][kc_column_text _id=”972837″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”891051″][kc_column_text _id=”342462″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Operator Interface” _id=”274788″][kc_row_inner column_align=”middle” video_mute=”no” _id=”160729″][kc_column_inner width=”50%” _id=”383437″][kc_single_image image_size=”full” _id=”13842″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”508214″][kc_column_text _id=”896866″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”1943″][kc_column_text _id=”24422″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Print Unit” _id=”23279″][kc_row_inner column_align=”middle” video_mute=”no” _id=”112160″][kc_column_inner width=”50%” _id=”213455″][kc_single_image image_size=”full” _id=”89640″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”86579″][kc_column_text _id=”561911″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”289214″][kc_column_text _id=”686713″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Sleeve Type Impression Assembly” _id=”755549″][kc_row_inner column_align=”middle” video_mute=”no” _id=”732060″][kc_column_inner width=”50%” _id=”287376″][kc_single_image image_size=”full” _id=”631918″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”261045″][kc_column_text _id=”827566″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”666745″][kc_column_text _id=”964235″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Transmission” _id=”326133″][kc_row_inner column_align=”middle” video_mute=”no” _id=”371750″][kc_column_inner width=”50%” _id=”23423″][kc_single_image image_size=”full” _id=”368486″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”726573″][kc_column_text _id=”114385″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”819745″][kc_column_text _id=”857174″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Drying System” _id=”133198″][kc_row_inner column_align=”middle” video_mute=”no” _id=”707907″][kc_column_inner width=”50%” _id=”313733″][kc_single_image image_size=”full” _id=”140359″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”240366″][kc_column_text _id=”204500″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”126416″][kc_column_text _id=”450578″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Out-Feed System” _id=”650946″][kc_row_inner column_align=”middle” video_mute=”no” _id=”977122″][kc_column_inner width=”50%” _id=”466341″][kc_single_image image_size=”full” _id=”342069″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”196590″][kc_column_text _id=”730494″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”882241″][kc_column_text _id=”868256″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Rewind Group” _id=”711151″][kc_row_inner column_align=”middle” video_mute=”no” _id=”956114″][kc_column_inner width=”50%” _id=”893094″][kc_single_image image_size=”full” _id=”583952″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”939456″][kc_column_text _id=”191239″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”326241″][kc_column_text _id=”410448″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”C.P.S System” _id=”105412″][kc_row_inner column_align=”middle” video_mute=”no” _id=”569937″][kc_column_inner width=”50%” _id=”51123″][kc_single_image image_size=”full” _id=”623136″ image_source=”media_library” image=”3462″][/kc_column_inner][kc_column_inner width=”50%” _id=”297840″][kc_column_text _id=”588190″]

Specially designed Cart facilitates ease for insertion and extraction from the printing station. Thanks to a special mechanism: Cart slides on linear guide rail which ensures perfect in & out operation; only one operator can easily carry out the operation.

To carry out loading I unloading of gravure cylinder there is a lifting system onboard on the cart, which consist of hydraulic piston, levers etc.

[/kc_column_text][kc_spacing height=”20″ _id=”661975″][kc_column_text _id=”665569″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][/kc_accordion][/kc_column][/kc_row][kc_row _id=”526329″][kc_column width=”12/12″ video_mute=”no” _id=”679397″][kc_single_image image_size=”1240×650″ _id=”697635″ image=”3772″ image_source=”media_library”][kc_row_inner column_align=”middle” video_mute=”no” _id=”225427″][kc_column_inner width=”60.09%” _id=”704190″][kc_spacing height=”25px” _id=”947062″][kc_title text=”Vk1DSCBDb2F0aW5nIE1hY2hpbmU=” _id=”499352″ type=”h2″][kc_spacing height=”20″ _id=”439476″][kc_column_text _id=”781995″ css_custom=”{`kc-css`:{}}”]

The machine has been specially designed, for various Primary Packaging Blister Coating and Food Packaging jobs on Heat Seal Lacquer applications.

Highly productivity, easy operating, optimum energy consumption and ability to handle wide range of Primer Coating and HSL coating jobs are the key features.

By perfectly integration of the latest generation of automation electronics and mechanical components, the machine is made to deliver optimum performance and productivity with minimum lest to right GSM Veration.

[/kc_column_text][kc_button text_title=”Brochure” _id=”219510″ link=”#||” show_icon=”yes” icon=”flaticon-download” icon_position=”left” custom_css=”{`kc-css`:{}}”][/kc_column_inner][kc_column_inner width=”39.87%” _id=”66931″][kc_spacing height=”40px” _id=”910810″][kc_raw_code code=”PHN0eWxlPg0KdGFibGUuYmx1ZVRhYmxlIHsNCiAgYm9yZGVyOiAxcHggc29saWQgIzFDNkVBNDsNCiAgYmFja2dyb3VuZC1jb2xvcjogI2Y1ZjVmNTsNCiAgd2lkdGg6IDEwMCU7DQogIHRleHQtYWxpZ246IGxlZnQ7DQogIGJvcmRlci1jb2xsYXBzZTogY29sbGFwc2U7DQp9DQp0YWJsZS5ibHVlVGFibGUgdGQsIHRhYmxlLmJsdWVUYWJsZSB0aCB7DQogIGJvcmRlcjogMXB4IHNvbGlkICMwMDAwMDA7DQogIHBhZGRpbmc6IDNweCA0cHg7DQp9DQp0YWJsZS5ibHVlVGFibGUgdGJvZHkgdGQgew0KICBmb250LXNpemU6IDEzcHg7DQogIGNvbG9yOiAjMDAwMDAwOw0KfQ0KdGFibGUuYmx1ZVRhYmxlIHRoZWFkIHsNCiBiYWNrZ3JvdW5kOiAjMGI1NDZiOw0KIGJhY2tncm91bmQ6IC1tb3otbGluZWFyLWdyYWRpZW50KHRvcCwgIzEyNmI4NyAwJSwgIzBiNTQ2YiA2NiUsICMwNjQ1NTkgMTAwJSk7DQogYmFja2dyb3VuZDogLXdlYmtpdC1saW5lYXItZ3JhZGllbnQodG9wLCAjMTI2Yjg3IDAlLCAjMGI1NDZiIDY2JSwgIzA2NDU1OSAxMDAlKTsNCiBiYWNrZ3JvdW5kOiBsaW5lYXItZ3JhZGllbnQodG8gYm90dG9tLCAjMTI2Yjg3IDAlLCAjMGI1NDZiIDY2JSwgIzA2NDU1OSAxMDAlKTsNCiAgYm9yZGVyLWJvdHRvbTogMnB4IHNvbGlkICM0NDQ0NDQ7DQp9DQp0YWJsZS5ibHVlVGFibGUgdGhlYWQgdGggew0KICBmb250LXNpemU6IDE1cHg7DQogIC8qIGZvbnQtd2VpZ2h0OiBib2xkOyAqLw0KICBjb2xvcjogI0ZGRkZGRjsNCiAgdGV4dC1hbGlnbjogY2VudGVyOw0KICBib3JkZXItbGVmdDogMnB4IHNvbGlkICMwMDMxNDA7DQp9DQp0YWJsZS5ibHVlVGFibGUgdGhlYWQgdGg6Zmlyc3QtY2hpbGQgew0KICBib3JkZXItbGVmdDogbm9uZTsNCn0NCg0KdGFibGUuYmx1ZVRhYmxlIHRmb290IHRkIHsNCiAgZm9udC1zaXplOiAxNHB4Ow0KfQ0KdGFibGUuYmx1ZVRhYmxlIHRmb290IC5saW5rcyB7DQogIHRleHQtYWxpZ246IHJpZ2h0Ow0KfQ0KdGFibGUuYmx1ZVRhYmxlIHRmb290IC5saW5rcyBhew0KICBkaXNwbGF5OiBpbmxpbmUtYmxvY2s7DQogIGJhY2tncm91bmQ6ICMxQzZFQTQ7DQogIGNvbG9yOiAjRkZGRkZGOw0KICBwYWRkaW5nOiAycHggOHB4Ow0KICBib3JkZXItcmFkaXVzOiA1cHg7DQp9DQo8L3N0eWxlPg0KDQo8c3R5bGUgdHlwZT0idGV4dC9jc3MiPg0KLnRnICB7Ym9yZGVyLWNvbGxhcHNlOmNvbGxhcHNlO2JvcmRlci1zcGFjaW5nOjA7fQ0KLnRnIHRke2JvcmRlci1jb2xvcjpibGFjaztib3JkZXItc3R5bGU6c29saWQ7Ym9yZGVyLXdpZHRoOjFweDtmb250LWZhbWlseTpBcmlhbCwgc2Fucy1zZXJpZjtmb250LXNpemU6MTRweDsNCiAgb3ZlcmZsb3c6aGlkZGVuO3BhZGRpbmc6MTBweCA1cHg7d29yZC1icmVhazpub3JtYWw7fQ0KLnRnIHRoe2JvcmRlci1jb2xvcjpibGFjaztib3JkZXItc3R5bGU6c29saWQ7Ym9yZGVyLXdpZHRoOjFweDtmb250LWZhbWlseTpBcmlhbCwgc2Fucy1zZXJpZjtmb250LXNpemU6MTRweDsNCiAgZm9udC13ZWlnaHQ6bm9ybWFsO292ZXJmbG93OmhpZGRlbjtwYWRkaW5nOjEwcHggNXB4O3dvcmQtYnJlYWs6bm9ybWFsO30NCi50ZyAudGctZGNkY3tmb250LXNpemU6MThweDsgYmFja2dyb3VuZC1jb2xvcjojMUU3M0JFO2NvbG9yOiNmZmZmZmY7IHRleHQtYWxpZ246Y2VudGVyO3ZlcnRpY2FsLWFsaWduOnRvcH0NCi50ZyAudGctMGxheHt0ZXh0LWFsaWduOmNlbnRlcjt2ZXJ0aWNhbC1hbGlnbjp0b3B9DQo8L3N0eWxlPg0KDQo8dGFibGUgY2xhc3M9InRnIj4NCjxjb2xncm91cCA+DQoJPGNvbCBzdHlsZT0id2lkdGg6NjAlOyI+DQoJPGNvbCBzdHlsZT0id2lkdGg6NDAlOyI+DQo8L2NvbGdyb3VwPg0KPHRib2R5Pg0KICA8dHI+DQogICAgPHRoIGNsYXNzPSJ0Zy1kY2RjIiBjb2xzcGFuPSIyIj5TdGFuZGFyZCBUZWNobmljYWwgU3BlY2lmaWNhdGlvbjwvdGg+DQogIDwvdHI+DQoNCiAgPHRyPg0KICAgIDx0ZD5NYWNoaW5lIFR5cGU8L3RkPg0KICAgIDx0ZD5WTUNIIFdJVEggT05MSU5FIFNIRUxMQUM8L3RkPg0KICA8L3RyPg0KICA8dHI+DQogICAgPHRkPk1hY2hpbmUgTW9kZWw8L3RkPg0KICAgIDx0ZD5QT0xFU1RBUiBDT0FUIDwvdGQ+DQogIDwvdHI+DQogIDx0cj4NCiAgICA8dGQ+Q29uZmlndXJhdGlvbjwvdGQ+DQogICAgPHRkPlRocmVlIHJvbGwgL0dyYXZ1cmU8L3RkPg0KICA8L3RyPg0KICA8dHI+DQogICAgPHRkPk1heC4gd2ViIHdpZHRoPC90ZD4NCiAgICA8dGQ+MTAwMG1tLjwvdGQ+DQogIDwvdHI+DQogIDx0cj4NCiAgICA8dGQ+TWluLiB3ZWIgd2lkdGg8L3RkPg0KICAgIDx0ZD40MDAgbW0uPC90ZD4NCiAgPC90cj4NCiAgPHRyPg0KICAgIDx0ZD5NYXguIFJlZWwgRGlhbWV0ZXI8L3RkPg0KICAgIDx0ZD44MDBtbSBhdCB1bndpbmQgJiByZXdpbmQuPC90ZD4NCiAgPC90cj4NCiAgPHRyPg0KICAgIDx0ZD5Db3JlIERpYW1ldGVyPC90ZD4NCiAgICA8dGQ+NzZtbSwgMTUybW08L3RkPg0KICA8L3RyPg0KICA8dHI+DQogICAgPHRkPk1heC4gd2VpZ2h0IG9mIHJlZWw8L3RkPg0KICAgIDx0ZD44MDBrZ3MuPC90ZD4NCiAgPC90cj4NCiAgPHRyPg0KICAgIDx0ZD5IZWF0aW5nIHR1bm5lbCBjaGFtYmVyPC90ZD4NCiAgICA8dGQ+OCAtMTAgbm9zLjwvdGQ+DQogIDwvdHI+DQogIDx0cj4NCiAgICA8dGQ+VHVubmVsIExlbmd0aDwvdGQ+DQogICAgPHRkPjEyIC0gMTUgbXRyPC90ZD4NCiAgPC90cj4NCjwvdGJvZHk+DQo8L3RhYmxlPg==” _id=”289098″][/kc_column_inner][/kc_row_inner][kc_row_inner _id=”919833″ cols_gap=”{`kc-css`:{}}” css_custom=”{`kc-css`:{`any`:{`box`:{`margin|`:`inherit inherit 50px inherit`}}}}”][kc_column_inner width=”33.33%” _id=”747237″][kc_spacing height=”50px” _id=”702762″][kc_single_image image_size=”1240×650″ _id=”959845″ image_source=”media_library” image=”3785″][/kc_column_inner][kc_column_inner width=”33.33%” _id=”316126″][kc_spacing height=”50px” _id=”532821″][kc_single_image image_size=”1240×650″ _id=”989553″ image_source=”media_library” image=”3786″][/kc_column_inner][kc_column_inner width=”33.33%” _id=”754595″][kc_spacing height=”50px” _id=”142048″][kc_single_image image_size=”1240×650″ _id=”193401″ image_source=”media_library” image=”3787″][/kc_column_inner][/kc_row_inner][kc_accordion _id=”639666″ css_custom=”{`kc-css`:{}}”][kc_accordion_tab title=”Control System” _id=”91052″][kc_row_inner column_align=”middle” video_mute=”no” _id=”745278″][kc_column_inner width=”50%” _id=”825188″][kc_single_image image_size=”full” _id=”169505″ image_source=”media_library” image=”3791″][/kc_column_inner][kc_column_inner width=”50%” _id=”682025″][kc_column_text _id=”803765″]

Servo cum AC Drive based closed loop controller for web handling by using latest generatton of electronics. Entire machine operation is controlled and supervises by high performance motion controller having its own intelligent software.

Master operator control panel consists of touch screen (HMI) operating interface facilitates ease in operation. Safety of operator, machine and electronic modules are achieved with the help of necessary hardware protection and intelligent software routines.

[/kc_column_text][kc_spacing height=”20″ _id=”100369″][kc_column_text _id=”329103″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Frame Structure” _id=”951490″][kc_row_inner column_align=”middle” video_mute=”no” _id=”890345″][kc_column_inner width=”50%” _id=”726452″][kc_single_image image_size=”full” _id=”631956″ image_source=”media_library” image=”3792″][/kc_column_inner][kc_column_inner width=”50%” _id=”126742″][kc_column_text _id=”691841″]

The sturdy heavy-duty frame structure designed carefully and methodically considering the precise accuracy to suit the specified running optimum speed over long dependable life. The precise frame mounting, linking and its balancing ensures less vibration and increase its reliability and durability.

[/kc_column_text][kc_spacing height=”20″ _id=”617842″][kc_column_text _id=”673571″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Unwinder & Rewinder” _id=”750743″][kc_row_inner column_align=”middle” video_mute=”no” _id=”654015″][kc_column_inner width=”50%” _id=”557401″][kc_single_image image_size=”full” _id=”332465″ image_source=”media_library” image=”3787″][/kc_column_inner][kc_column_inner width=”50%” _id=”64885″][kc_column_text _id=”994443″]

Unwinder- Rewinder

Unwind & Rewinder Unit Comprises of width Steel Plate with supporting bearing Brackets with moving trolley. This entire assemblage makes roll exchange extremely fast, easy and reduces job time.

Technical Features:

⦁ Maximum diameter of reel : 800MM

⦁ Maximum weight of reel : 800kgs

⦁ Internal diameter of core for shaft : 76mm & 152mm

⦁ Web tension range : 60-400N

⦁ Web tension regulation : Load-Cell Base

Composition:

Load cell roll-based web tension control system consists of…

⦁ Closed loop Vector controller AC frequency drive.

⦁ Pair of load cell for actual tension display and tension feedback.

⦁ AC motor complete with encoder, timing belt pulleys etc

⦁ Air shaft with Safety chucks/Mechanical Housing.

⦁ Shaft body and shaft end journals from steel.

Unwind web tension control:

Web tension control system by using latest generation AC drive with AC motor, load cells. The system maintains tension precisely throughout the reel run.

The system is composed of:

⦁ AC drive & AC motor

⦁ Load cell roller assembly for tension feedback & actual tension display on HMI

[/kc_column_text][kc_spacing height=”20″ _id=”767040″][kc_column_text _id=”483597″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Primer Coating Unit” _id=”608656″][kc_row_inner column_align=”middle” video_mute=”no” _id=”557530″][kc_column_inner width=”50%” _id=”669555″][kc_single_image image_size=”full” _id=”139747″ image_source=”media_library” image=”3786″][/kc_column_inner][kc_column_inner width=”50%” _id=”304417″][kc_column_text _id=”110570″]

Primer Coating unit.

Exceptionally designed, and precisely machined, strong and robust steel frame structure, maintains accuracy over long dependable life and ensures reduced vibration even with optimum line speed.

Primer Unit system pulls the substrate from unwinding station and at the same time retains required set tension between Shellac and Coating unit precisely and isolates the Shellac unit from tension disturbance of the unwinding zone.

Composition:

⦁ Load cell base roller for auto tension feedback

⦁ AC motor complete with related assembly

⦁ NIP Rubber Roller with pneumatically adjustable pressure.

⦁ Specially designed pneumatically operated doctor blade assembly ensures a straight profile of the blade resulting in lesser blade pressure, better printing quality and longer cylinder life.

⦁ Gravure system at coating unit.

⦁ Flame proof Motor with adhesive pump and SS tank. for Adhesive viscosity maintain

[/kc_column_text][kc_spacing height=”20″ _id=”404233″][kc_column_text _id=”915040″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Bottom Tendency” _id=”166396″][kc_row_inner column_align=”middle” video_mute=”no” _id=”405769″][kc_column_inner width=”50%” _id=”875311″][kc_single_image image_size=”full” _id=”579985″ image_source=”media_library” image=”3794″][/kc_column_inner][kc_column_inner width=”50%” _id=”501914″][kc_column_text _id=”560307″]

Heating tunnel is divided into Zones. All Drying Zone hinged at rare end and enabled to get opened with the help of pneumatic cylinder. The heating tunnel will be accessible by catwalk throughout tunnel length. Idler rollers are driven by timing belt and pulley. Chrome plated/ Teflon coated idle rollers are dynamically balanced and polished provided in the tunnel to guide the web. Tunnel (which is exposed to the atmosphere) is connected to each compartment is insulated to preserve the heat loss.

[/kc_column_text][kc_spacing height=”20″ _id=”619107″][kc_column_text _id=”378659″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Coating Unit” _id=”553805″][kc_row_inner column_align=”middle” video_mute=”no” _id=”706487″][kc_column_inner width=”50%” _id=”2401″][kc_single_image image_size=”full” _id=”138980″ image_source=”media_library” image=”3785″][/kc_column_inner][kc_column_inner width=”50%” _id=”179577″][kc_column_text _id=”451652″]

Coating Unit: (Heat Seal Lacquer /VMCH)

Steel frame Structure with cross connection Tie Bar Plates, coating unit is linked with shellac unit. It ensures that mechatronics are synchronized at any desired speed. Distinctively designed, and precisely machined, strong and robust steel frame structure, maintains accuracy over long dependable life and ensures reduced vibration even with optimum line speed.

Composition

⦁ One AC vector drives control, motor with Gear box Remote digital panel.

⦁ Three Roll Systems width rubber rolls with Assembly which insure minimizing Left to Right Coating GSM

⦁ Chilling Roll before Coating

⦁ Load cell base roller for auto tension feedback

⦁ Double jacket Ink Tray with Assembly with manual up down working.

⦁ Coating unit 3 Phase AC motor

⦁ Transparent Inspection Box to Inspect Coated Film.

[/kc_column_text][kc_spacing height=”20″ _id=”880991″][kc_column_text _id=”580536″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Top Tendency” _id=”335834″][kc_row_inner column_align=”middle” video_mute=”no” _id=”695453″][kc_column_inner width=”50%” _id=”235036″][kc_single_image image_size=”full” _id=”352803″ image_source=”media_library” image=”3793″][/kc_column_inner][kc_column_inner width=”50%” _id=”196363″][kc_column_text _id=”456859″]

All Drying Zone hinged at rare end and enabled to get opened with the help of pneumatic cylinder. The heating tunnel will be accessible by catwalk throughout tunnel length. Idler rollers are driven by timing belt and pulley. Chrome plated/ Teflon coated idle rollers are dynamically balanced and polished provided in the tunnel to guide the web. Tunnel (which is exposed to the atmosphere) is connected to each compartment is insulated to preserve the heat loss.

Adhesive drying is obtained by centrally connected hot air input on the web through air nozzles. The optimized airflow lessens heat consumption and avoids solvent retention in the coated substrates. Solvents evaporation is obtained by air nozzles, blowing air on the web in connection with the idle rollers, in order to ensure the drying, avoiding shaking or deforming of the web itself. The optimized airflow minimizes heat consumption and avoids solvent retention in the printed substrate.

The central exhaust system is controlled by heavy-duty centrifugal exhaust blower to collect solvent contaminated air from all the tunnel units through central ducts/piping fitted with manual adjustable damper.

[/kc_column_text][kc_spacing height=”20″ _id=”655614″][kc_column_text _id=”816855″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Chilling NIP” _id=”957246″][kc_row_inner column_align=”middle” video_mute=”no” _id=”286110″][kc_column_inner width=”50%” _id=”232141″][kc_single_image image_size=”full” _id=”135961″ image_source=”media_library” image=”3790″][/kc_column_inner][kc_column_inner width=”50%” _id=”619773″][kc_column_text _id=”620203″]

CHILLING/ NIP CONSOLE:

It is a Steel frame Structure with cross connection Tie Bar Plates, Chilling unit ensures that mechatronics are synchronized. Distinctively designed, and precisely machined, strong and robust steel frame structure, maintains accuracy over long durability and ensures reduced vibration even with optimum line speed.

Two chilling rolls are tightly synchronized together with ac motor Driven by AC vector drive. The rotary union is provided to ensure chilled water circulation uniformly.

[/kc_column_text][kc_spacing height=”20″ _id=”432210″][kc_column_text _id=”564441″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][kc_accordion_tab title=”Idle Roller” _id=”240046″][kc_row_inner column_align=”middle” video_mute=”no” _id=”912769″][kc_column_inner width=”50%” _id=”193501″][kc_single_image image_size=”full” _id=”212658″ image_source=”media_library” image=”3798″][/kc_column_inner][kc_column_inner width=”50%” _id=”732881″][kc_column_text _id=”696273″]

Specially designed, low friction-low inertia, dynamically balanced idle rollers, mounted on low friction bearings to enhance rotational smoothness. Properly grooved, ground and balanced the rollers are made of specially graded anti-corrosion aluminum alloy.

[/kc_column_text][kc_spacing height=”20″ _id=”843094″][kc_column_text _id=”640010″]

- Possibility to remove only the inking system, leaving the printing cylinder in the printing station

- Possibility to remove only the printing cylinder, leaving the inking system in the printing station

- Possibility to remove the printing cylinder together with the inking system at the same time

[/kc_column_text][/kc_column_inner][/kc_row_inner][/kc_accordion_tab][/kc_accordion][/kc_column][/kc_row]