Sublimation Paper Coating

Sublimation Paper Coating

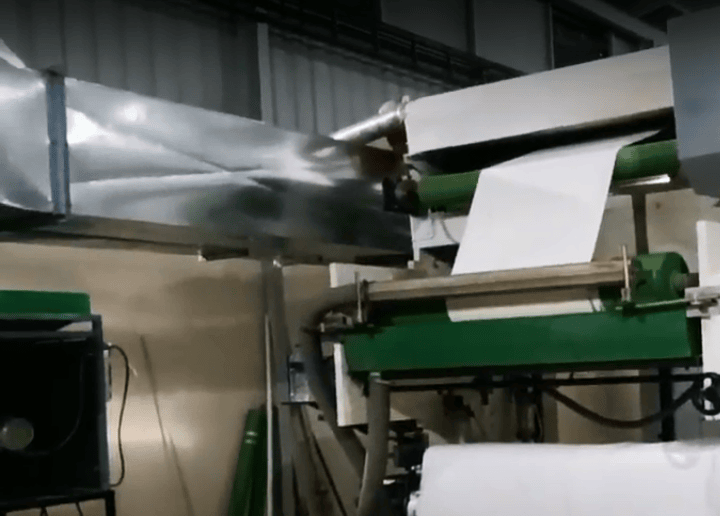

The machine has been specially designed, for Textile Sublimation Coating Application.

Sublimation paper is applicable to sublimation transfer, on which can print images with mirror reversal through inkjet printing, flat printing, screen printing, and gravure printing. Then transfer the image onto media by heating and pressuring, which makes ink on the paper become a gaseous state and combine with the media.

Key Features:

⦁ High Productivity

⦁ Easy Operating

⦁ Optimum energy consumption and ability to handle wide range of coating jobs

By perfect integration of the latest generation of automation electronics and mechanical components, the machine is made to deliver optimum performance and productivity with minimum left to right GSM Variation.

| Standard Technical Specification | |

|---|---|

| Machine Type | Sublimation Paper Coating WITH ONLINE SHELLAC |

| Machine Model | POLESTAR COAT-SPC |

| Configuration | Reverse Gravure / Airknife / Fine Bar |

| Max. web width | 1000mm-2250mm. |

| Min. web width | 400 mm. |

| Max. Reel Diameter | 800mm at unwind & rewind. |

| Core Diameter | 76mm, 152mm |

| Max. weight of reel | 800kgs. |

| Heating tunnel chamber | 8 -12 nos. |

| Tunnel Length | 12 - 18 mtr |

Control System

Servo cum AC Drive based closed loop controller for web handling by using latest generation of electronics. Entire machine operation is controlled and supervised by high performance motion controller having its own intelligent software.

Master operator control panel consists of touch screen (HMI) operating interface facilitates ease in operation. Safety of operator, machine and electronic modules are achieved with the help of necessary hardware protection and intelligent software routines.

Frame Structure

The sturdy heavy-duty frame structure designed carefully and methodically considering the precise accuracy to suit the specified running optimum speed over long dependable life. The precise frame mounting, linking and its balancing ensures less vibration and increase its reliability and durability.

Unwinder & Rewinder

Unwind & Rewinder Unit Comprises of width Steel Plate with supporting bearing Brackets with moving trolley. This entire assemblage makes roll exchange extremely fast, easy and reduces job time.

⦁ Maximum diameter of reel : 800MM

⦁ Maximum weight of reel : 800kgs

⦁ Internal diameter of core for shaft : 76mm & 152mm

⦁ Web tension range : 60-400N

⦁ Web tension regulation: Load-Cell

Base Composition: Load cell roll-based web tension control system consists of…

⦁ Closed loop Vector controller AC frequency drive.

⦁ Pair of load cell for actual tension display and tension feedback.

⦁ AC motor complete with encoder, timing belt pulleys etc

⦁ Air shaft with Safety chucks/Mechanical Housing.

⦁ Shaft body and shaft end journals from steel.

Unwind web tension control:

Web tension control system by using latest generation AC drive with AC motor and load cells. The system maintains tension precisely throughout the reel run.

The system is composed of:

⦁ AC drive & AC motor

⦁ Load cell roller assembly for tension feedback & actual tension display on HMI

Coating Unit:(Heat Seal Laquer/VMCH)

⦁ One AC vector drives control, motor with Gear box Remote digital panel.

⦁ Three Roll Systems width rubber rolls with Assembly which insure minimizing Left to Right Coating GSM

⦁ Chilling Roll before Coating

⦁ Load cell base roller for auto tension feedback

⦁ Double jacket Ink Tray with Assembly with manual up down working.

⦁ Coating unit 3 Phase AC motor

⦁ Transparent Inspection Box to Inspect Coated Film.

Top Tendency

Chilling/NIP Console

Idle Roller