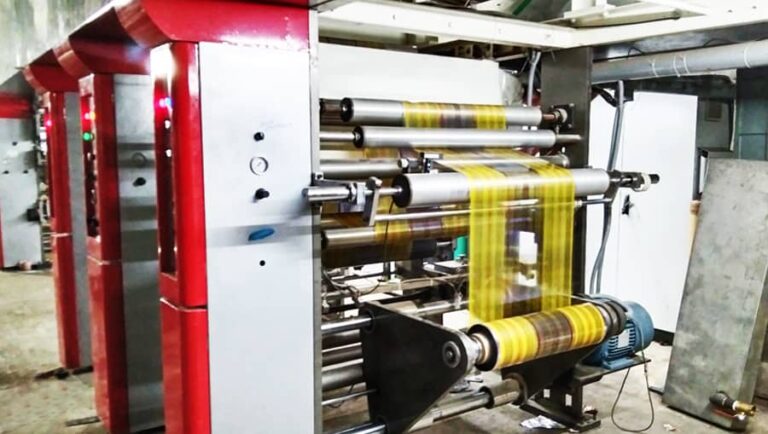

Solvent Based Dry Bond Lamination Machine

Polestar -DL - 220

Polestar - DL - 220

The machine has been specially designed, focusing on various flexible packaging jobs on solvent-based applications over plastic printed or plain films.

The most important characteristics are its capacity to handle a wide range of laminating tasks, ease of operation, and optimal energy consumption.

The machine is designed to provide optimal performance and productivity by perfectly integrating ergonomically designed mechanical components with the latest generation of electronics.

| Standard Technical Specification | |

|---|---|

| Machine Speed | 220m/min |

| Machine Web Width | 750mm to 1500mm |

| Core Diameter for unwinders | 3" (76mm) & 6" (152mm) |

| Core Diameter | 6" (152mm) |

Control System

Servo based shut circle regulator for web taking care of by utilizing most recent age of gadgets. Whole machine activity is controlled and manages by elite execution movement regulator having its own wise programming. The master operator control panel has a touch-screen interface that makes it easier to use. Wellbeing of administrator, machine and electronic modules are accomplished with the assistance of important equipment insurance and insightful programming schedules

Frame Structure

Unmistakably planned and unequivocally machined, solid and durable, steel outline structure, with hardening tie-poles; maintains accuracy over a long, dependable life and, even at maximum line speed, guarantees less vibration. The structure gives the working area more light. Each component’s mechanical construction, which is subjected to numerous tests, guarantees optimal performance and longer equipment life.

Shaft-Less Unwinders & Rewinders Group

Shaft-less unwind & rewind web tension controlled by using latest generation Servo Motor and Servo Drive The system maintains the set tension precisely throughout the reel run The system mainly composed of AC Servo Drive and Servo Motor, pneumatically loaded low friction dancing roller assembly and load cell for tension feed-back and actual tension display. The unwind & rewind arms move on high precision linear bushings and supported on ground chromeplated steel bars.

Laminating Unit

Doctor Blade Group

Specially designed doctor blade group ensures a straight profile of the blade resulting in lesser blade pressure, better printing quality and longer cylinder life.

Coating Unit

Coating unit is transmitted by an AC servomotor through a gear Box. Speed can be set by means of push buttons and monitored on the display (touch screen or HMI) The AC servo drive ensures that the set speed ts maintain.

Drying System

Idle Roller